Back-to-the-Future Concept Spurs Product Lifecycle Revolution

The technically gifted, business-minded MBA alumnus Michael Grieves, Ph.D., came up ushered in an exciting revolution: digital twins for designing, testing, manufacturing and supporting the product in the virtual world

For some, managing a Fortune 100 company’s mainframe operations in their early 20’s might be the pinnacle of their career. For Michael Grieves, it was just the beginning.

Attending Oakland University’s summer math camp as a high-school junior jump started a career now replete with accomplishments for this alumnus, who graduated from OU's charter MBA program in 1979.

"At camp, we learned to program Fortran on OU's mainframe, which led to a path in the computer industry,” says Dr. Grieves, who also has a bachelor’s degree in computer engineering and a doctorate in executive management in business. “With that technical experience and later MBA equipping me with business tools, OU was instrumental in determining my future.”

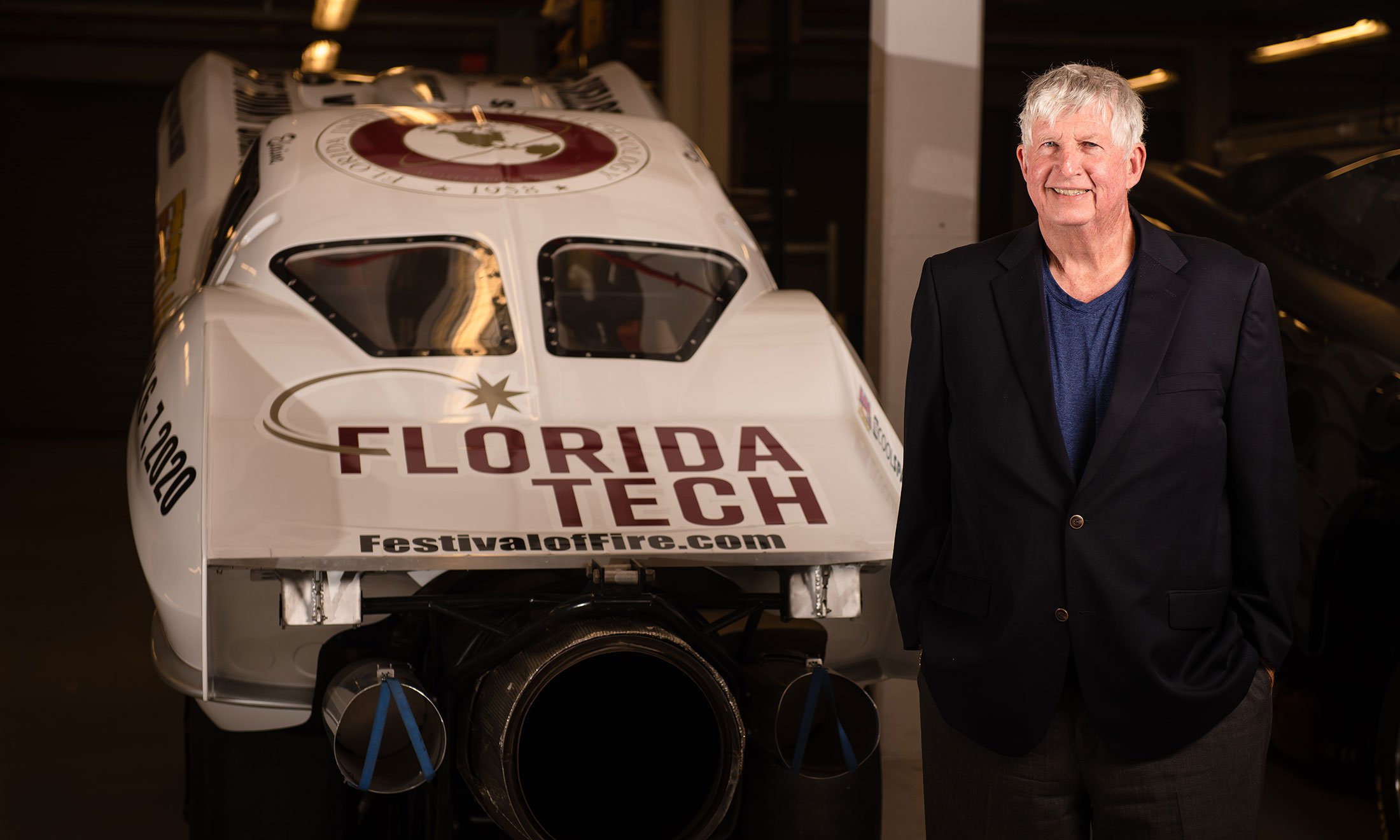

Now research professor and chief scientist for Florida Institute of Technology's Center for Advanced Manufacturing and Innovative Design, Dr. Grieves is a world-renowned authority in Product Lifecycle Management (PLM). He writes and lectures extensively on the topic and is a frequent keynote speaker. He’s also a consultant for many leading international manufacturers and government organizations, including NASA.

PLM’s focus is in maintaining information about a product throughout its entire lifecycle — design-build-maintain-dispose — reducing time, energy and cost.

“Once engineers develop a product, they often don’t know what happens to it after that,” says Dr. Grieves. “PLM is a back-to-the-future approach, like in the days of the cobbler. Cobblers knew their customers well and were physically involved, working and reworking their product, while keeping precise records – keeping customers satisfied, while reducing waste [the cobbler’s time/energy/supplies].”

But how can beginning-to-end attention to a product be accomplished in the complex, modern era of engineering and manufacturing? The technically gifted, business-minded Dr. Grieves came up with an idea, ushering in an exciting revolution: digital twins.

Doubling up

Dr. Grieves first introduced the digital twin concept/model for designing, testing, manufacturing and supporting the product in the virtual world in 2002. Although virtual models have been around for decades, the digital twin required advancements in machine-to-machine communication and automation technologies. Technology has now caught up with the concept, allowing industries such as automotive, aerospace and healthcare to reap benefits.

A digital twin is a form and function model of the actual product, which incorporates its 3D geometry, mechanical properties, electrical/electronic systems and simulated performance data. The real-world product’s data interacts with and updates the model in real time, allowing for product problems to be spotted early.

“For places like NASA, ‘oops’ is an expensive word,” Dr. Grieves says. “We need to correct product mistakes in the digital world, not the physical world. In terms of healthcare, extensive simulation work before actual patient care is another obvious, important benefit.”

In addition to the safety, cost and quality efficiencies, Dr. Grieves points to exciting possibilities in expanding the use of digital twins in intelligent design predictor mode.

“With the [2009] Air France Flight 477 crash, the pilots continued performing the same [incorrect] action over and over,” says Dr. Grieves. “With a digital twin to show what would happen 30 minutes later in flight, they might have been able to correct their course. Another area where predictors could have life-saving consequences is surgery.”

In collaboration with NASA Principal Technologist John Vickers, Dr. Grieves moves forward with research as executive director of the Digital Twin Institute – but he still looks back.

He remains invested in the university that provided his first computer-related opportunity and the business principles to last a lifetime. Dr. Grieves serves as Chairman Emeritus of OU's School of Business Board of Visitors. He and his wife, Diane (MGT '83), support a computer lab in Elliott Hall and an MIS business diversity scholarship.

“I realized early on I wanted to use virtuality to do valuable things,” he reflects.

Mission accomplished – and continued.

April 07, 2020

April 07, 2020

By Mary Gunderson-Switzer

By Mary Gunderson-Switzer